It is a PC application where shipment orders are optimally planned with appropriate pallet types and simulated in three dimensions in the office environment. Users can intervene in the planning if they deem necessary, or the system can continue automatic planning from the point where they left off. The capabilities of the system can be improved by creating loading templates for original product pallets or specific combination products. The approved pallet plans are then planned for the vehicle or container for a second time, and with user approval, the final load plans are recorded in the system and loading lists are created. Loading patterns can also be visually recorded and presented to those who will perform the physical operation. FSM-X (Vehicle and Load Planning System) consists of 2 main modules as Server and Client applications. Windows 2003-2008 Server operating system and SQL Server 2005-2008 database management systems must be installed on the server. MS Windows (XP, Vista, Windows7) applications must be installed on client computers.

FSM Scope

- Pallet Planning

- Container Planning

- Vehicle Planning and Vehicle Type Determination

- Manual + Automatic Planning Options

- Creating Upload Templates

- Pallet, Container and Vehicle Simulations in 3D environment

- Reporting Operations

User Login

After selecting the Company and User, enter the User Password and press the OK button (or Enter key).

Main Screen and Functions

The main screen of the application is divided into 3 main groups.

Definitions

Definitions is a heading group that covers the screens where the basic definitions used by the system are made.

Transactions

This is the group heading where all operational processes are applied.

View

This is the group heading where the theme color and menu layout of the system is set.

Defining Company Information

Company Information is entered for information purposes and has no operational importance.

However, Parameter Information is designed for Operational Preferences, where the "Product Based Loading" parameter is a parameter that aims to keep the same products together as much as possible. (Using Product Based Loading will slightly reduce efficiency).

Template Loading Priority is the parameter that determines whether single product pallet templates or mixed templates will be prioritized.

User Information and Authorization

If the name entered by entering the User Name and pressing the "Enter" key is available; the relevant record is brought to the screen, if not, the data field is activated for the new entry process.

Entering User Name, User Description and Password Information is sufficient for the vehicle loading module.

If the warehouse application will be integrated with Depo-X, "User Type" must be selected.

Office User : It is the user type that can only work on the desktop application.

Field User : It is the type of user (personnel) that will work with hand terminal (RF).

Both users : It is the user type that has the right to use for both desktop and hand terminal application.

User authorization is done on the basis of Application Menu.

Select the user and give the List command, all authorizations defined for the user are selected in the menu list.

For the authorization to be removed, the selection mark on the relevant menu step is removed.

Defining Company Information

Company accounts that will be needed during order entry are defined with the Company Information Definition process.

Product-Part Identification

Product Shape indicates whether the part to be loaded is cubic (parcel) or cylindrical (barrel, pipe, etc.).

Movement permissions refer to the available placement of the part (parcel) on the pallet.

The Loading Group Code ensures that parts that cannot be placed on top or that are marked as Placed on Bottom Only can be loaded exceptionally within the same group.

The Overlayable option must be selected for overlay to be possible.

If the parameter "Placed on Base Only" is selected, the product can only be loaded on the pallet base or on itself.

Defining Product Loading Groups

Loading Groups in part product definitions are defined with this screen.

Defining Pallet Information

In Pallet Information, the Fixed Height / Variable Height option indicates whether the pallet has a fixed volume in the form of a crate or whether it is a standard pallet such as Iso, Euro, etc.

If the Weight control is selected, the loading will end for that pallet when the weight of the parts loaded in the pallet reaches the Max Weight.

The only options "Settles on the base" and "Loaded on" provide the same function as the parameters on the part.

Defining Vehicle Information

Order Entry Processes

Order Entry operations are performed by using the new button from the screen opened with the Order Entry button under the Operations menu group.

The validity date on the order refers to the last date to be displayed in the Vehicle and Pallet Loading application. Thanks to the relevant date, only active orders will be reflected on your screen.

Note: Information such as retrospective order review, loading details, etc. can be accessed by expanding the date range on the Order main screen.

If this date is before the loading date, that order will not appear on the loading screen, it will become visible again after the order validity period is updated. With the order closing process, orders that are finished are removed from the loading screen.

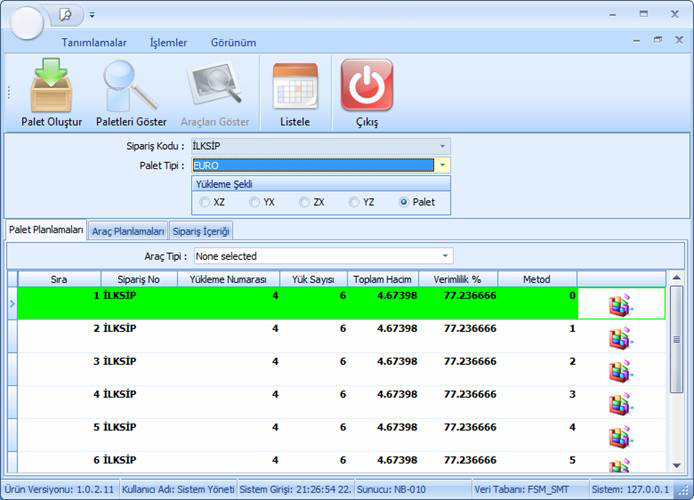

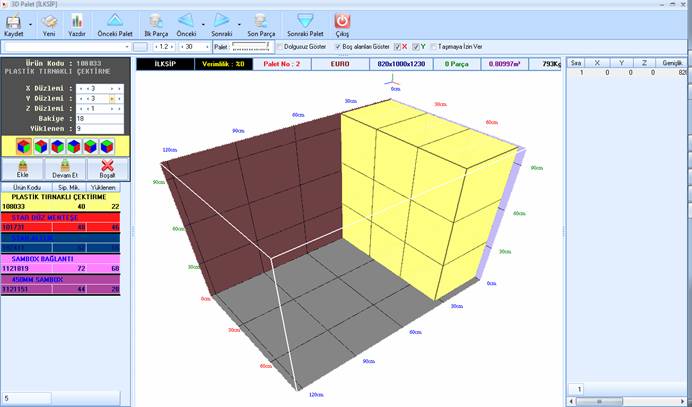

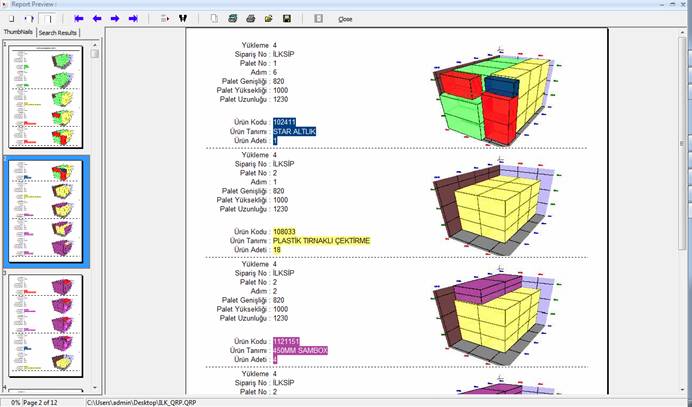

Pallet Creation Process

Pallet Creation can be accessed with the "Pallet and Vehicle Loading" button under the Operations menu group.

The order whose details are defined on the order entry screen must be selected on the Pallet loading screen.

After selecting the Order Code and Pallet Type, the Loading method is selected;

XZ: Loading is firstly loaded in X plane (pallet width) and then in Z plane (pallet depth). Then the loading continues in Y plane (pallet height) as folded.

YX: Loading is first loaded in the Y plane (pallet height) and then in the X plane (pallet width). Loading then continues in the Z plane (pallet depth).

ZX: Loading is first loaded in the Z plane (pallet depth), then in the X plane (pallet width). Loading is then continued in the Y plane (pallet height) in layers.

YZ: Loading is first loaded in the Y plane (pallet height), then in the Z plane (pallet depth). Loading is then continued in the X plane (pallet depth).

Pallet: This type of loading involves the widest possible spread on the base.

By selecting the relevant order, pallet and the loading method detailed above, the Create Pallet button is used and the pallet is created in accordance with the details given.

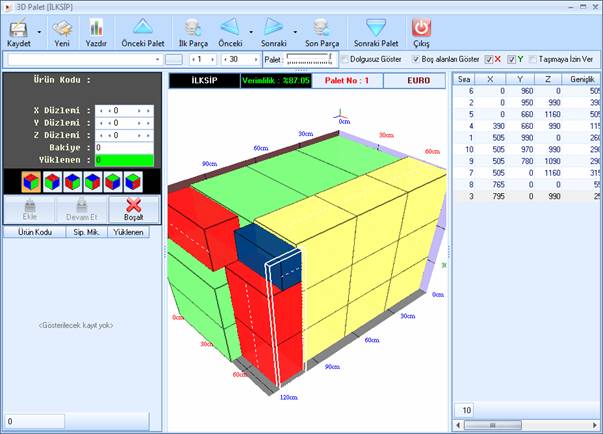

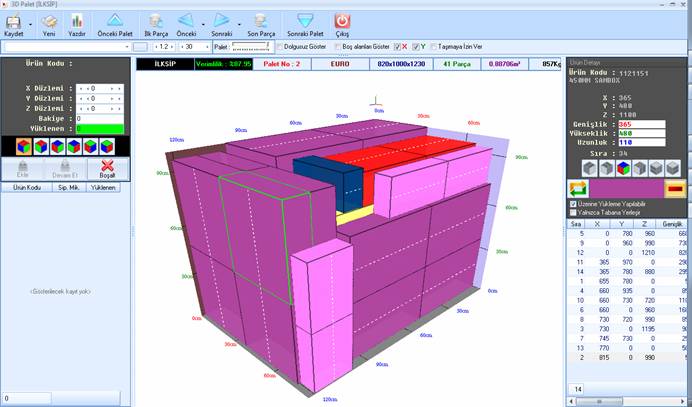

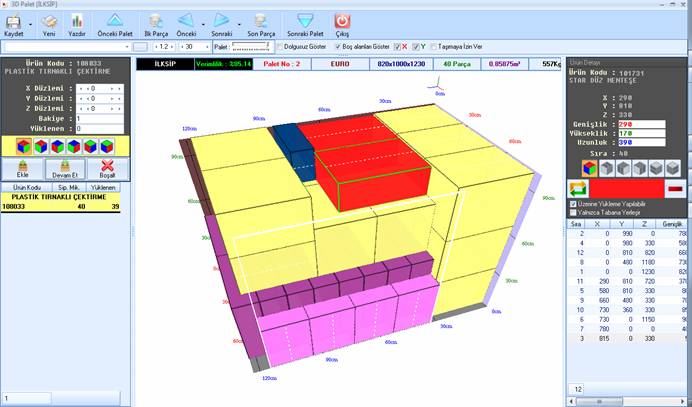

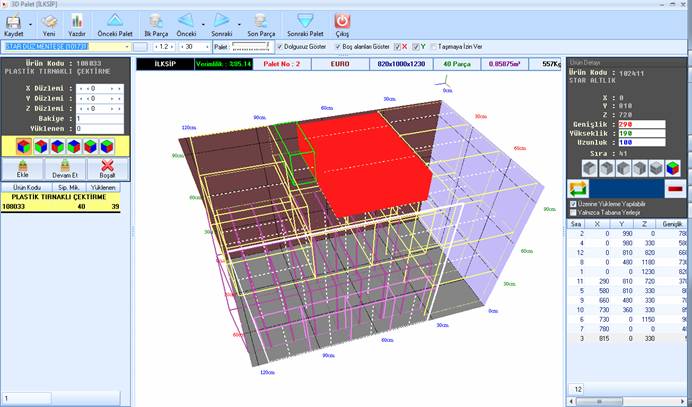

The pallets created with the Show Pallets button are called to the screen.

Previous Pallet and Next Pallet buttons can be used to switch between pallets.

Previous and Next Buttons are used to see the processes from the first part to be placed on the pallet to the last part to be placed on the pallet. (You can see the step-by-step part sequence and the way it is placed on the pallet.)

The First Part Button completely unloads the pallet and the next button shows the first part to be placed on the pallet.

The Last Piece button will display the final loaded pallet on the screen.

After selecting a part in the palette, the selected part is deleted from the palette by pressing the Delete button or by pressing the Delete button.

On the left side of the screen, the order balances are listed and on the right side, the empty spaces that can be used are listed.

The order balances on the left side of the screen are placed on the relevant pallet by using the Continue button in line with the values given to the X, Y and Z planes.

Aktif yükleme için Yazdır butonu tıklanarak adım adım yükleme reçetesi oluşturulur. İlgili reçete dosya olarak kaydedilir yada yazdır butonu ile yazdırılır.

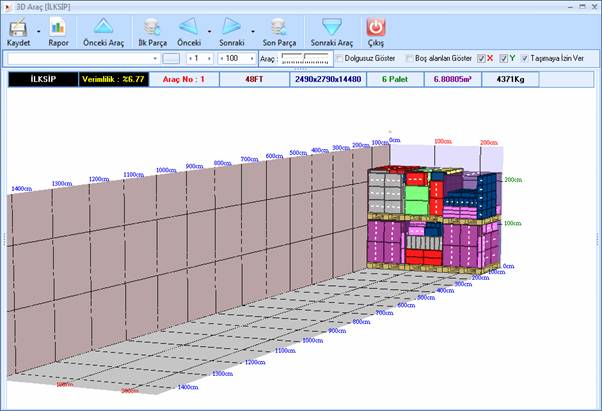

Vehicle Creation Planning

Vehicle creation and Pallet creation processes work with the same logic

.